E-Bulb

The smallest fire extinguisher in the world

Which fire extinguisher for an electrical fire?

Fires regularly break out in electronics.

Before a major electrical fire starts, the world's smallest fire extinguisher automatically extinguishes

the source of danger directly inside the media technology. Through this the E-Bulb makes safe devices even safer.

E-Bulb

The smallest fire extinguisher in the world

Fires regularly break out in electronics.

With the E-Bulb, safe devices can be made even safer.

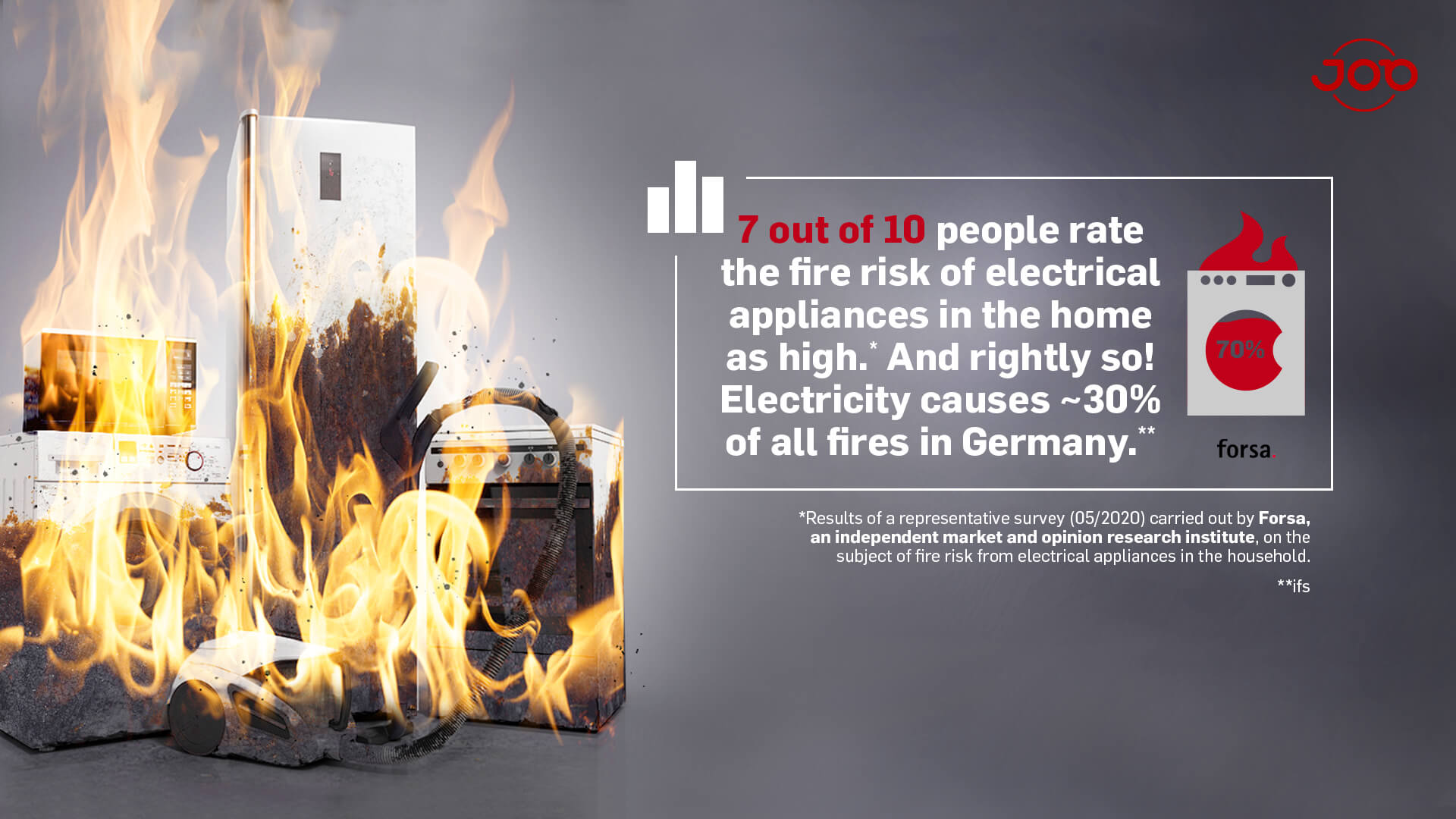

30% of all fires are caused by electricity, many of them in electrical appliances

Source: ifs-ev.org 2022, Causes of Fire Damage Statistics

Business interruption is the greatest risk for companies (caused, among other things, by fires)

Source: Allianz Risk Barometer 2020

Around every third fire is caused by electricity, many from electrical appliances. Quality-conscious manufacturers have been providing the industry with safe products for years. The causes, which can lead to a technical defect, and possibly fire, can never be completely eliminated.

Common causes of fire:

- Plug connections

- Voltage fluctuations in the power grid

- Component failure

- Operation out of specification

- Aging

- Environmental conditions

- Cold solder joints

- Manufacturing fault

- and many more!

Since many fires occur in electrical devices, it makes sense to extinguish the fire as early as possible, and directly at the place of origin. The electric fire is best contained when it is still small.

A sprinkler system, e.g. in one room, is the best way to prevent a fire from spreading to other rooms or the entire building. Our device-integrated fire protection implements the concept for electrical devices with extinguishing agents directly at the source of a fire in the device itself.

What is the E-Bulb?

The E-Bulb is a fire-extinguishing fuse and consists of a coated glass ampoule filled with non-toxic extinguishing agent. The smallest version is just two centimetres tall, as small as a typical micro fuse. This makes the E-Bulb the smallest fire extinguisher in the world.

And this is how the fire extinguishing fuse works:

The fire is detected at the origin and the fire is automatically extinguished. The power is permanently cut off to prevent re-ignition and a message is automatically sent. This prevents high consequential fire damage and reduces the risk of business interruption. Based on sprinkler glass technology that has been proven a billion times over, while the E-Bulb was developed.

The E-Bulb can be built into the electronics by electrical appliance manufacturers and protect electronic equipment from damage. If an electrical device develops a technical fault, the E-Bulb can detect the fire, extinguish it, and prevent it from reigniting.

For which electrical appliances can the E-Bulb be used?

The areas of application for E-Bulbs are broad and varied. They range from power adapters in advertising screens (media technology), to ventilators in medical technology, and household appliances in homes. The E-Bulb can be easily installed in the electronics and protects your electrical devices 24/7 even without power and in stand-by.

The E-Bulb is a CIFEA (UL 60692) and a UL recognized component

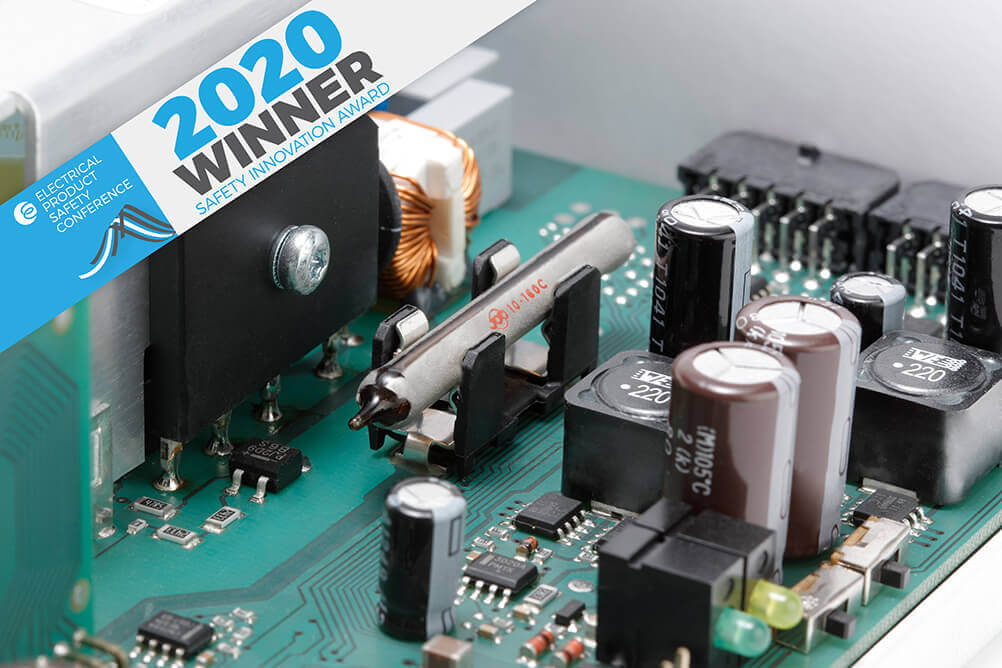

Example: This is how the E-Bulb is installed in electrical appliances

Use our interactive slider to see how the E-Bulb is integrated into an electrical appliance - with the example of a coffee machine.

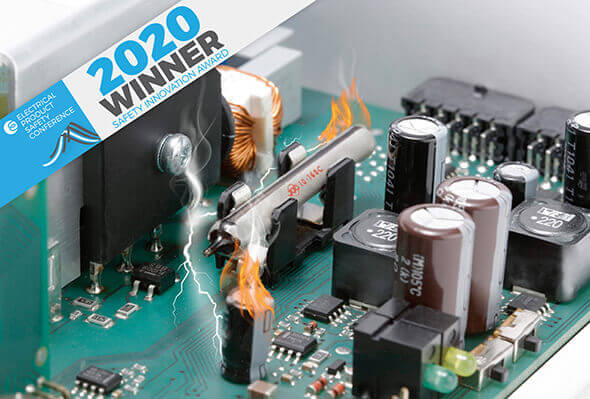

Winner of the Safety Innovation Award 2020

The E-Bulb won the 2020 UK Safety Innovation Awards for the best innovative development.

With its advantages and unique selling points, the E-Bulb was able to stand out and win the competition in the end! The award is presented by Electrical Safety First. This award was created to recognize and reward the outstanding product safety initiatives within the industry. Learn more at Electrical Safety First. Electrical Safety First.

How can the investment be earned back?

The E-Bulb is an innovation that protects and saves costs.

An innovation that pays off and saves lives. Find out 6 reasons why spending money on the E-Bulb will soon pay off. Just click on the advantages and learn more.

Reduce product recall costs

Example:

Due to the high risk of fire, every major household appliance manufacturer has had to recall ranges of appliances in recent years. This can lead to a loss of image, which can be prevented easily: Through the use of E-Bulbs manufacturers operate preventive fire protection and product recall costs can be reduced significantly. Sometimes the need to recall the entire range can be avoided. For individual defective devices, it is a simple service case

Example Calculation:

200,000 Recall Units x $50 Recall Costs = $10m Costs + Significant Reputational Damage

vs. Material Costs x Production Quantity = Positive Business Case

Reduce

costs

Beim Design von Elektronik können unterschiedliche Brandschutzkonzepte zum Einsatz kommen. Unser Anspruch ist es, die Sicherheit von Elektrogeräten zu erhöhen. Durch den Einsatz von E-Bulbs lassen sich die Gesamtproduktkosten reduzieren, etwa durch die Reduktion bzw. den Ersatz von flammhemmenden Materialien. Diese Materialien stehen darüber hinaus oft in der Kritik umweltschädlich zu sein.

Easy building

approval

Switch from being classified as “causing a fire” to “being involved in a firerisk assessment”. This is especially relevant for sensitive locations, such as shopping centres, exhibition halls, airports, or train stations. The installation and use of equipment-integrated fire protection, such as E-bulbs, makes electrical equipment such as digital signage and LED advertising screens safer. This also means that printers, screens or billboards can gain installation approval, even in escape route areas.

Protection against

business interruptions

The use of E-Bulbs can protect against business interruptions, or shorten the interruption time. Every third fire in Germany causes over €500,000 of property damage in the industry, so much that the affected companies can’t recover. Only 23% of all firms affected by a fire completely reopen their business again. While more than 40% of companies have to stop trading after a fire.

- Hospital: In England there are over 550 fires in hospitals every year, statistically that’s 1.5 per day. Often the origin of these fires are located in electrical equipment. Medical technology devices with built-in E-Bulbs reduce the risk of fire. They also increase the safety for patients and protect against commercial and asset loss, as well as interruptions to healthcare services.

- Hotel: Consider a fire breaking out in a hotel minibar. Without fire protection integrated into the device, only the sprinkler system protects the hotel. The rooms are usually locked down for a few days and cannot be booked, leading to a loss of income. In the event of a fire an E-Bulb in the minibar would allow the refrigerator to be replaced quickly, the guests would be unaware, and normal operations could continue. That makes the combination of sprinkler systems and device-integrated fire protection essential.

- Industry:The cost of business interruptions in the industry is rapidly increasing. Securing production-relevant systems, by installing E-Bulbs as a secondary protection within power supplies, both pays off and iseconomically advantageous.

Accepted by

insurers

The operation of electrical devices with device-integrated fire protection (e.g. E-Bulb) is accepted and promoted by insurance companies. For manufacturers it involves product liability and the insurance for recall costs. For operators it is relevant for fire and business interruption insurances. Its use makes it easier to take out the general insurance, and for many insurance companies the use of integrated fire protection solutions is even relevant for bonuses. Please consult your insurance company.

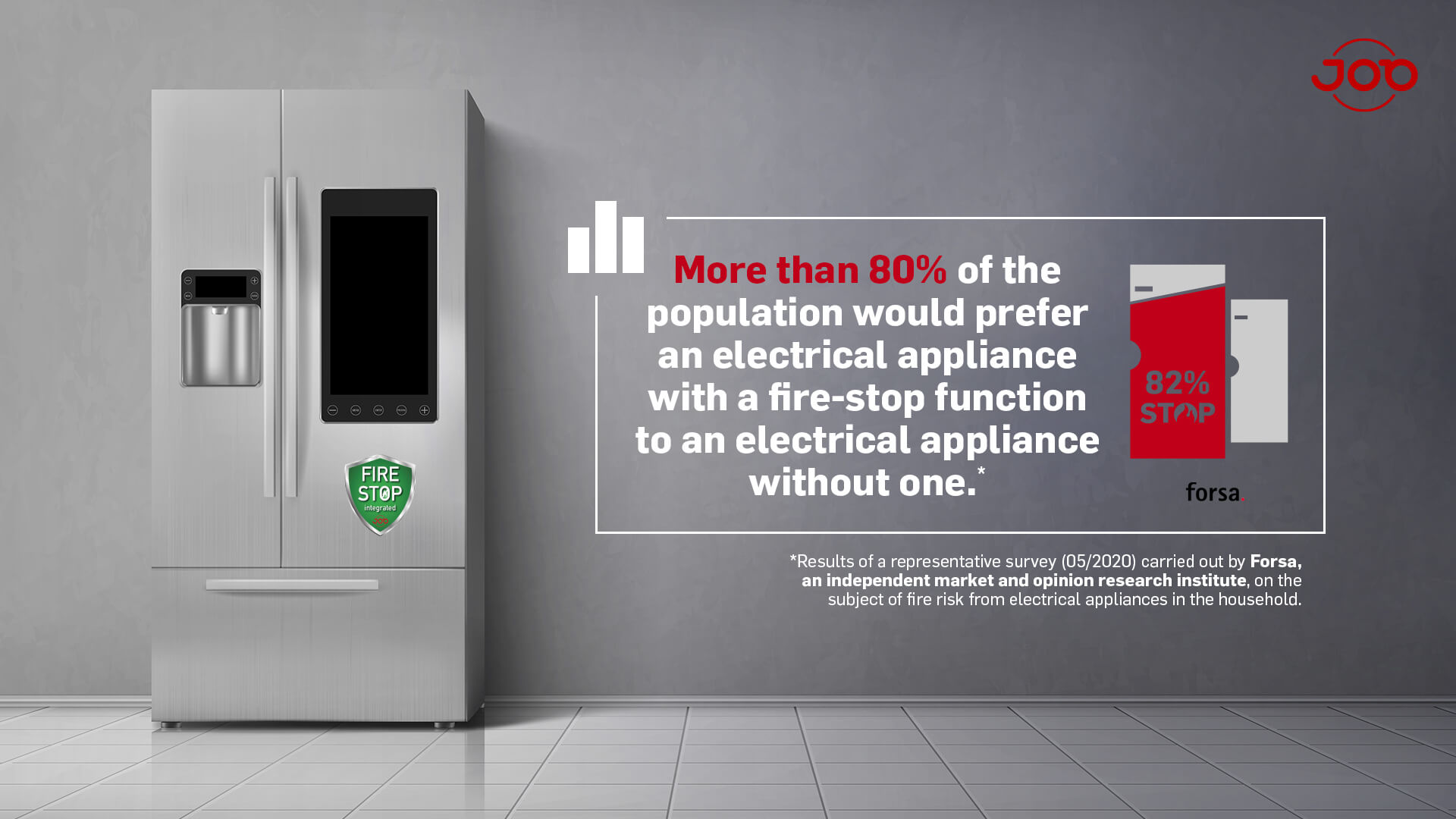

Integrated fire-stop as a unique selling point

As a manufacturer or operator, you can get ahead of your competitors with the E-Bulb because:

- Safety as a product characteristic is valued by customers and leads to higher customer satisfaction

customer satisfaction. - A device-integrated fire stop as a unique selling point, can secure market shares

- Preventive fire protection as a USP in the industry can help to win commissions.

- The E-Bulb can help to market the added value to consumers of a device-integrated fire-stop, as a built-in fire extinguisher.

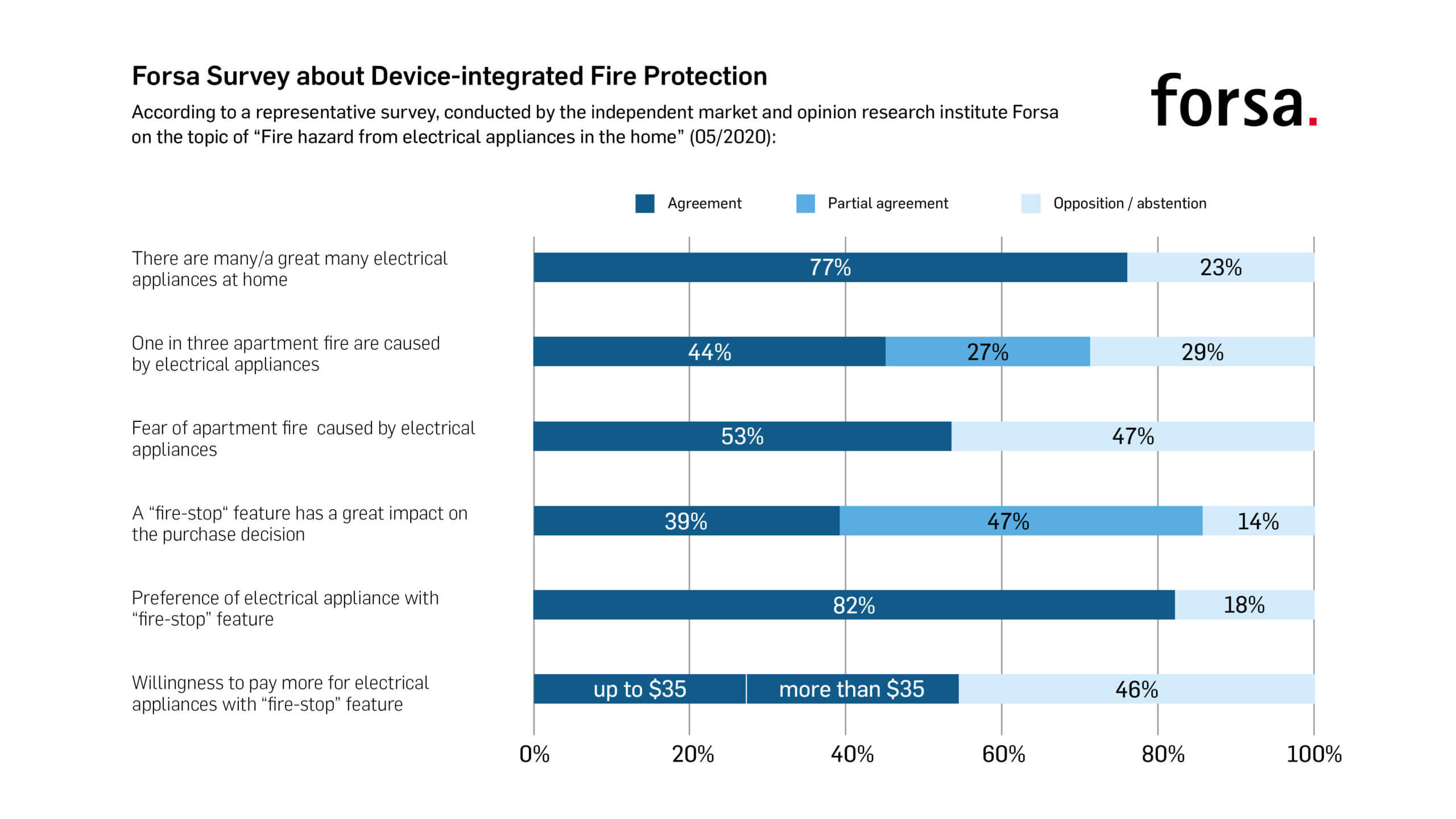

Consumers appreciate the added value of devices with an integrated fire stop

E-Bulb as a safety feature makes your

product marketable

According to a representative survey, conducted by

the independent market and opinion research institute Forsa on the topic of

“Fire hazard from electrical appliances in the home” (05/2020)

Innovation pioneers

Industry voices

International Association

of Fire and Rescue Services (CTIF)

"Walton TV with integrated E-Bulb fire safety is aligned to achieve our vision for 2030. Our aim is to increase the safety of Walton Television and other appliance. E-Bulb fire safety electric device will increase our product safety and brand value. So by ensuring our product and our customers' safety Walton television will boost globally as a top electronic brand. This will help us to achieve vision 2030."

“Preventing a fire is always better than putting a fire out. This new technology is taking the right approach and could become an important building block for preventive fire protection. Should it prove itself, manufacturers should build it into their devices from the outset."

International Association

of Fire and Rescue Services (CTIF)

"The integrated protection of electrical devices, through device-integrated fire protection, is a good idea and can have a positive effect on the insurance bonuses."

"As a distributor for components, and a valued partner for electronical development, we recommend integrated fire protection, and the E-Bulb, particularly as "secondary protection” to our customers.”

"Through the use of device-integrated fire protection in modern media technology, from LED walls and digital signage, to information points and product presentation applications, as an innovative system provider we have the opportunity to deliver even more creative and flexible building projects for our customers."

BEN HUR GmbH

"It helps the fire brigade enormously when measures have been implemented in the electronics to tackle or even extinguish fires when they first break out."

"These extinguishing bulbs should be integrated into all electrical devices (power packs, power electronics) that are operated unattended or run in stand-by! The bulbs are triggered when a fire breaks out, extinguish it and interrupt the power supply. Really useful technology ..."

Where is the E-Bulb already state-of-the-art?

Selected case studies

Case Study Media Technology

Wherever people gather in large numbers, fire protection plays an important role. This especially applies to the airport in Frankfurt, Germany’s largest and most frequented airport, with almost 200,000 passengers a day (2019), and over 81,000 employees. The safety requirements for the technical infrastructure are accrodingly high. Thanks to an invention by Job GmbH, electronics company Samsung has received approval to install large format LED media screens at the airport. From the point of view of fire protection experts, the E-Bulbs prevent screens from being classified as fire originators, allowing them to be used in more fire-sensitive locations.

Case Study Medical Technology

Statistically, a fire breaks out in a German hospital every weekElectrical devices are often the origin of these fires. Recently, the need for ventilators has increased worldwide, due to the coronavirus pandemic. Ventilators can also be made even safer - tragically, several patients died in St. Petersburg and Moscow in May 2020 due to fires caused by respiratory equipment.

Fire protection for medical technology: Device-integrated fire protection can be installed in the majority of medical devices at limited cost. Increasingly, medical technology companies are opting for device-integrated fire protection, and you?

Case Study Home Appliances

Refrigerators, dishwashers, televisions:Most people have many electrical appliances at home. However, since then the fire risk has increased, as most electrical devices now run permanently, while constantly drawing electricity: Every electrical device which remains ‚on‘ is a potential fire hazard.

Fortunately, the vast majority of electrical household appliances are safe. At the same time the reasons for a fire to start vary and a fire risk can never be completely ruled out. Knowing their home appliance has a built-in mini fire extinguisher to minimize the fire risk, relieves many people.

Case Study Elektronics

The following practical examples point out how diverse the areas of application for E-Bulbs are:

Power supply units & control devices: E-Bulbs are already installed in electrical power devices, as an additional protective measure, to protect against consequential fire damage, in the event of technical defects, and to minimize business interruptions.

Lighting and digital infoscreens: E-Bulbs are inserted in industrial warehouse lighting to minimizethe inherent risk of fire from the LED modules, drivers and plug contacts.

Solar Panel Systems: The integrated fire-stop E-Bulb leads to a safe power interruption and prevents larger fires on the carrier systems.

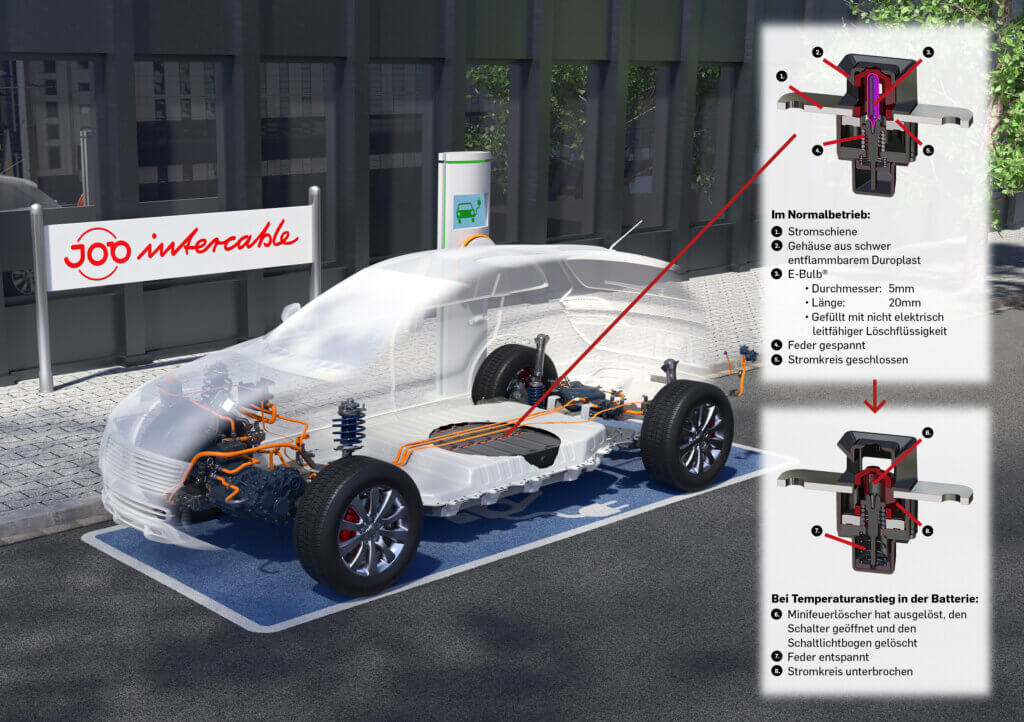

Case Study Automotive

E-mobility calls for new fire protection concepts. Together with the automotive supplier intercable we have developed a thermofuse.

The e-bulb is installed in a flame-retardant housing. If the temperature rises above the limit, it bursts and activates a mechanism that interrupts the current flow and thus reduces the voltage by switching off the battery segments. This greatly reduces the risk of short circuits and arcing or injury from electric shock.

Minimize the fire risk of electric cars.

A joint development by intercable and JOB

Technical specifications

E-Bulb

Extinguish electrical fire

&

Interrupt power supply

Small

- Irreversible power interruption

- Prevention of re-ignition

- Fire extinguishing function

-

Extinguishing agent:

FK-5-1-12 - Protected volume [Liters]: 0,416

- Protected volume [fl oz]: 14

-

Activating temperature:

135°C – 165°C - Max. Continuous ambient temperature: +85°C

- Current load per Version:

<1A, <5A, <10A, <16Apossible - Voltage: 0..250V AC/DC

- Minimum operating-/Storage temperature: -40°C/-40F

Medium

- Irreversible power interruption

- Prevention of re-ignition

- Fire extinguishing function

-

Extinguishing agent:

FK-5-1-12 - Protected volume [Liters]: 1,049

- Protected volume [fl oz]: 35 ½

-

Activating temperature:

135°C – 165°C - Max. Continuous ambient temperature: +85°C

- Current load per Version:

<1A, <5A, <10A, <16Apossible - Voltage: 0..250V AC/DC

- Minimum operating-/Storage temperature: -40°C/-40F

Large

- Irreversible power interruption

- Prevention of re-ignition

- Fire extinguishing function

-

Extinguishing agent:

FK-5-1-12 - Protected volume [Liters]: 2,212

- Protected volume [fl oz]: 75

-

Activating temperature:

120°C – 165°C - Max. Continuous ambient temperature: +85°C

- Current load per Version:

<1A, <5A, <10A, <16Apossible - Voltage: 0..250V AC/DC

- Minimum operating-/Storage temperature: -40°C/-40F

Recognised and confirmed by:

Note:

The E-Bulb is a CIFEA (UL 60692) and a UL recognized component

Other sizes, activation temperatures and uncoated variants (only extinguishing function) are available on request.

Information on “litres” and “fl oz”: In accordance with NFPA 2001 “Clean Agent Extinguishing Systems”.

We protect larger volumes with the AMFE, as illustrated below. AMFE.

E-Bulb news coverage

Benefits in one glance

- Improved safety

- Cost effective

- Easy installation

- Maintenance-free

- No further consequential damage

- 100% Made in Germany

How can the E-Bulb be integrated into electronics?

Step 1:

Identification of hotspots

Step 2:

Positioning the

E-Bulb in the product design

Step 3:

Bestätigung der Position durch Simulation & Brandversuche

Step 4:

E-Bulb protects the device from the inside

Are there any open questions?

Contact us! We’ll support you

to make your electronics even safer.

Your Contact

Markus Fiebig

Senior Product & Business Development Manager

Device-Integrated Fire Protection

Phone +49 4102 2114-223

Mail: markus.fiebig@job-group.com

JOB GmbH

Kurt-Fischer-Str. 30

22926 Ahrensburg

Germany